This article is original from TonyPromos.com blog by Tony Chen:

http://www.tonypromos.com/12-ways-logo-printing/

“How is Logo printing?”

“How you add my logo on product?”

“is it any other way for my Product Logo printing?”

Quite a lot of customer asked me.

Below Our Team Tonypromos sorted 12 ways for the logo printing/adding logo,sharing the knowledge which factory will never tell you.

#1 Silk Screen Printing

The first technique is silk screen printing. A stencil of your logo will be made on the silk screen where the ink can only pass through the stenciled image.

The printing is done when the ink is forced through the screen using a squeegee, forming the image of your logo on any product of your choice.

This printing technique can be used for stationeries, clothes (T-Shirts, Polos, etc.), toys, suitcases and bags, wooden products, shopping bags, silicone bracelets, umbrellas etc.

Silk screen originated from China and has over 2000 years of printing history.

This kind of printing produces very dependable, durable and longer-lasting prints.

However, silk screen printing can only be used to print on flat surfaces. Curved and uneven surfaces will not allow the stenciled logo to be correctly printed.

Also, one color can only be applied at a time. A logo with different colors will need different silk screens and stencils for every area where the color needs to be printed.

If a logo uses only two (2) colors for printing, the Minimum Order Quantity (MOQ) and the mold fee are quite lower compared to the other printing techniques and will only take 2-5 days to finish the printed product.

#2 Pad printing

This technique is also called “Ink pick-up and transfer“.

Pad printing utilizes a silicone pad that “picks up” the ink from an etched logo design and “transfers” or stamps it on the desired product.

This printing technique is ideal for electronic products, stationary, wooden products, jewelry, toys etc. This is also good for personalized and souvenir items like pens, ID holders, cups, mugs, USB flash drives, power banks etc.

Compared to the silk screen technique, pad printing can print on curved and uneven edges, and can print smaller designs and other details.

This kind of logo printing produces very dependable, durable and longer-lasting prints.

If a logo uses only two (2) colors for printing, the Minimum Order Quantity (MOQ) and the mold fee are quite lower compared to the other printing techniques and will only take 2-5 days to finish the printed product.

#3 Heat-Transfer Printing

Also called sublimation printing, the heat-transfer technique utilizes a computer to layout the desired logo or design. This logo or design is then printed on a transfer film, which is heat-pressed onto the product in order to transfer the logo or design.

Heat-transfer logo printing is more glossy and bright-colored. This kind of printing is ideal for ceramic kitchenware, shopping bags, plastic items, fabric, personalized or souvenir items like mugs, glasses, cloth, magic bandanas, non-woven bags, etc.

Heat-transfer is a good option for you if you have a SMALL quantity of orders and if your logo printing has more than four (4) colors.

No MOQ required; a minimum of one piece per order is accepted. The printing fee is higher compared to the first two techniques (silk screen and pad printing). Normally, the bigger the logo, the higher the cost of the printing fee,

eg.15X15cm logo, the printing fee is about 65USD.

#4 Embroidery

This technique utilizes an embroidery machine to print out your logo or pattern. The machine can print a variety of designs with different colors and patterns on any textile of your choice.

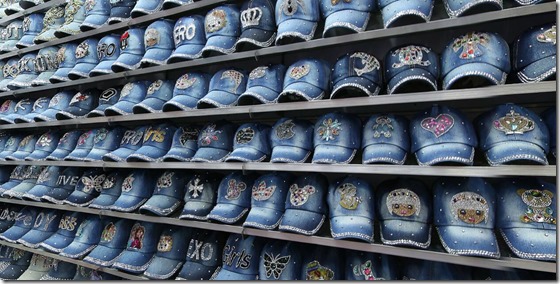

This logo printing is ideal for cloth bags, shirts, caps, personalized or souvenir items like schoolbags, knitted hats, etc.

Normally used on textile products, this printing can make patterns and logos that are bright-colored and 3D.

A good embroidery machine will make a good embroidered logo and there are no limits for the logo colors.

The MOQ requires a minimum of 500pcs per order and needs a longer production time of 15-20days.

#5 Jacquard knitted

The fifth printing technique is called Jacquard knitted.

The design for the product will be entered into the jacquard machine and the machine will automatically knit the cloth in the desired setting.

Once your logo is entered into the machine, the cloth will come out with the pattern on it once it starts production.

This logo printing is ideal for personalized or souvenir products like scarves, knitted gloves, knitted hats, towels, banners, etc.

The jacquard machine is capable of making simple patterns and logos.

The MOQ requires a minimum of 500pcs per order and needs a longer production time of 20- 25 days.

#6 UV Printing

UV printing is also called digital printing.

UV printing uses a photosensitizer ink material + UV light to make an all-powerful printer that can print on almost any material or product.

This logo printing technique is ideal for toys, electronic products, gift packing material, banners, ceramic items, metal items, souvenir or personalized products like big maps, tiles, good quality catalogues, etc.

UV printing (digital printing) uses Eco-friendly ink. The print speed is very slow so the cost will be higher, and will be charged according to printing size.

No MOQ required; a minimum of one piece per order is accepted.

eg., 1 pc of 1m x 1m map needs 10USD cost.

#7 Laser Engraving

The laser engraving technique uses a laser light to engrave on the product’s surface to make a pattern.

There are two kinds of lasers:

A. Cool laser– used to engrave onto metal products. It operates like a mini-hammer that makes indentions at the surface of the metal surface. The indented part shows the inner color of the metal according to the design or pattern.

B. Heat laser- used to engrave onto non-metal products. It operates by focusing a light beam to the surface of the product and slightly burns the surface of the product according to the design or pattern.

Laser engraving can be done on metal surfaces, wooden surfaces, glass items, plastic items, leather products, and other personalized or souvenir items like keychains, crystal trophies, wood coasters, beer openers, etc.

Cool laser

Heat laser

This logo printing entails the LOWEST cost compared to ALL the other printing techniques.

This kind of printing makes very wonderful outcomes on logo designs. No MOQ required; a minimum of one piece per order is accepted.

The item below was laser engraved. Can’t believe it?

Yes! Laser engraving is even possible on a delicate surface, such as glass.

The laser is adjusted so that the intensity doesn’t go through the glass material but reaches only a little of the surface, enough to engrave a design or a logo.

#8 Offset Printing

Offset printing uses rollers that transfer the design to the paper.

Two top rollers will keep the supply of ink to the plate cylinder and the plate cylinder will transfer the design to the offset cylinder, and the impression cylinder will print on the paper in a continuous cycle.

In two minutes, the printer can continuously print up to 100 pieces of paper.

This logo printing is ideal for packing material, books, newspapers, and personalized or souvenir products like calendars, packaging boxes, playing cards, etc.

Offset printing is faster and has good quality.

Due to the nature of offset printing, the MOQ is high—with a minimum quantity of 1000 pieces per order.

But what if you need only 200 pieces but you want offset printing? It’s okay. The print factory will charge a minimal handling fee to make this possible.

#9 Sticker (label) Printing

Using a sticker it is the easiest way to add a logo. You can just use a normal printing machine to print on a sticker paper and stick it on your product.

This printing is ideal for barcodes, glass bottle decorations, marking instructions, etc.

Stickers/labels are easily removed and can fall off. This is better used for Fast-Moving Consumer Goods like drinks, food products, etc., because of its short service life.

#10 Crystal Epoxy Sticker Printing

The Crystal epoxy sticker printing is just like the sticker printing but with an additional feature.

First, you print the sticker/label design, and then add AB glue on it. After the glue becomes solid, it will become “round”(like the water on a lotus leaf).

With solid glue, the sticker has a more 3D feel and maintains the bright-colors.

This printing can be used for toys, jewelry, crafts, souvenir or personalized items like keychains, pins, ID cards, etc.

Compared to the normal sticker, the Crystal Epoxy Sticker feels more luxurious and sturdy. It’s waterproof and scratch resistant, leading to a longer lifespan.

No MOQ required; a minimum of one piece per order is accepted.

#11 Hot Stamp Printing

Hot Stamp Printing uses a heated die and a hot stamp foil to make a print on the product.

You just need to heat the logo mold, press it on the product, and the desired logo will be impressed on your product.

If you want a silver or gold stamp, just add a sliver/gold film between the molding and the product.

This printing is ideal for leather items, suitcases, stationery, personalized or souvenir items like belts, wallets, books, gift cards, etc.

A hot stamp logo makes your product look more classy and expensive.

The hot stamp can only be done on soft materials and can’t be done on metal items.

The molding fee is 65USD for a 5x3cm logo.

#12 Debossed & Embossed Printing

For this printing, a mold is built with the debossed /embossed logo. After injecting (on silicone or rubber) or stamping (on stainless steel or iron), the logo becomes a part of the product.

This printing can be used on silicone items, rubber items, metal items, souvenir or personalized items like keychains, silicone bracelets, etc.

The molding fee for plastic and metal items is around 1,000 USD, but for silicone and rubber items, the molding fee is lower, depending on the size.

For example, a silicone bracelet with these dimensions: length- 202mm, width- 12mm, thickness, 2mm; will only have a 30 USD mold fee.

For more information about promos, visit TonyPromos.com/blog